|

| TEL(Chinese Service): |

| (86) 139 0527 0123 |

| (86-514) 8795 9766 |

| TEL(English Service): |

| (86) 139 0527 6765 |

| (86-514) 8582 9916 |

| FAX:86-514)87958766 |

| E-MAIL:ttepc@ttepc.com |

| ADD:13F, Jiuzhou Bldg, No. 143, M Jiangyang

Rd, Yangzhou City, Jiangsu Prov, P.R.China, 225009 |

|

|

|

Electric furnace congregation |

Technical key point: |

According to the discrepancy of electric furnace's flur gas temperature, different heat exchanging sides are set in flue gas waste heat recovering system. In the high temperature flue gas area, radiation heat transfer-oriented evaporative cooling combustion chamber and evaporative cooling flue are set, in the low temperature flue gas area, heat convection oriented heat recovery boiler is set. The electric furnace flue gas is extracted from the No. 4 hole inside the furnace, the temperature drops to about 850?? after passing through water-cooling bend, slide bushing, evaporative cooling combustion sedimentation chamber and evaporative cooling flue; it drops to around 200?? after going through heat recovery boiler, it is emitted into atmosphere after temperature drop mixed with secondary fume, then purified and dedusted by flue gas cleaning system. |

| |

Thermodynamic system: |

According to the factories' specific circumstances, there are the following 2 types of thermodynamic systems for electric furnace cogeneration system as follows: |

| |

| |

|

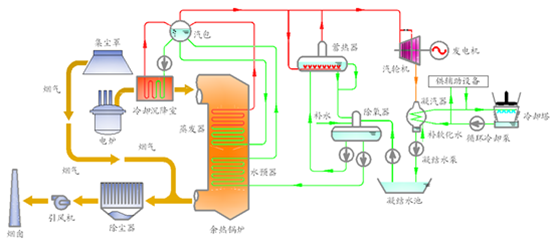

| Electric furnace saturated steam generation thermodynamic system |

| |

|

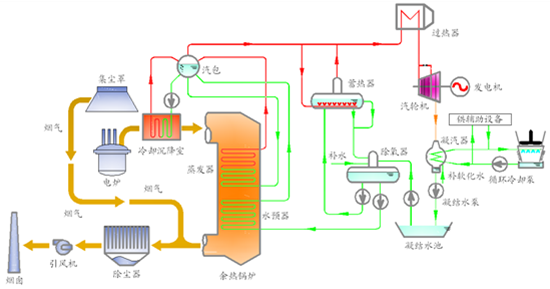

| Electric furnace superheated steam generation thermodynamic system |

| |

|

|

|