|

| TEL(Chinese Service): |

| (86) 139 0527 0123 |

| (86-514) 8795 9766 |

| TEL(English Service): |

| (86) 139 0527 6765 |

| (86-514) 8582 9916 |

| FAX:86-514)87958766 |

| E-MAIL:ttepc@ttepc.com |

| ADD:13F, Jiuzhou Bldg, No. 143, M Jiangyang

Rd, Yangzhou City, Jiangsu Prov, P.R.China, 225009 |

|

|

|

Converter, AOD refining furnace cogeneration |

Technical key point: |

Steelmaking converter and AOD refining furnace will generate plenty of high temperature flue gas in the blowing process(in general, the temperature of converter is more than 1300??, AOD refining furnace's temperature will even reach over 1800??, for the flue gas containing CO may generate much higher temperature after mixed firing with the absorbed air at the fire hole.) |

| |

Currently, water-cooling with high operating cost is commonly applied in AOD refining flue gas cooling treatment, while the mass sensible heat of the flue gas is not sufficiently used, huge waste of heat energy resources are created. |

| |

Today, in order to reduce the temperature of flue gas and recycle the waste heat in high temperature flue gas, the systematic set is equipped with stove-piped evaporative cooling waste heat boiler. Being impacted by the smoke fluctuation during blowing of converter, waste heat boiler will generate saturated vapour only during blowing period(??15min) within the entire smelting cycle(??30min), at the same time, due to the dramatic change of the flue gas quantity during blowing period, the quantity of the vapour generated by waste heat boiler is also rapidly fluctuated with it. To guarantee the consistency and stability of the turbine's admission flowing amount, a heat accumulator is usually equipped with. |

| |

The high temperature flue gas generated during blowing period generates steam-water mixture of 1.0??1.6MPa after heat exchange in evaporative cooling stack, the mixture is then sent to heat recovery boiler drum, the saturated vapour is sent out after steam-water separation in steam drum, some vapour gets into heat accumulator and then be injected into cold water through internal heat-filling device, vapour heats the supercooled water inside heat accumulator and condensates it to water at the same time to form saturated water, which enhances the enthalpy value of the water in the heat accumulator, thus the heat filling process of the heat accumulator is done; the other portion of vapour is delivered to steamer generator room through pressure regulating valve. The evaporative cooling waste water boiler generates no steam during non-blowing period of the converter, the vapour pressure close to the pressure regulating valve is constantly decreasing, at this time, the low pressure inside the heat accumulator drops, the saturated water is boiling after becoming superheat water and generates saturated steam, the saturated steam is delivered to turbine generating room through pressure regulating valve.

|

| |

In consideration of extending turbine blade's service life, improving generating efficiency, reducing gas consumption, enhancing generating profit, shortening investment cycle, the overheated steam system has been added in the system.

|

| |

Thermodynamic system: |

According to the factories' specific circumstances, there are the following 2 types of thermodynamic system for converter cogeneration system as follows:

|

| |

|

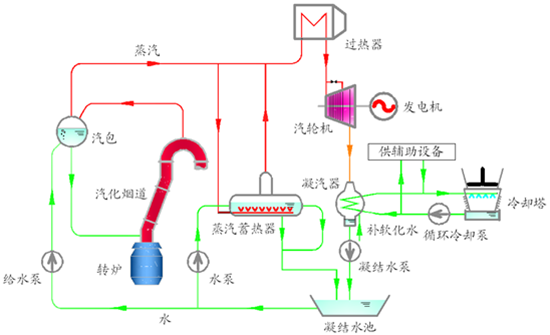

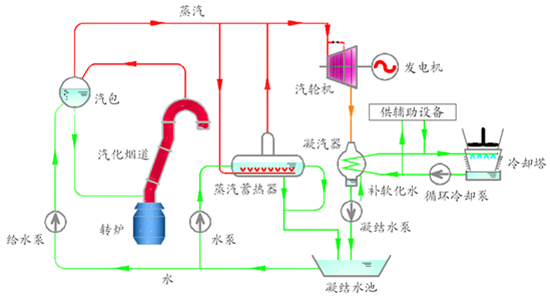

| Converter, AOD saturated steam generation thermodynamic system |

| |

|

| Converter, AOD superheated steam generation thermodynamic system |

| |

|

|

|