|

| TEL(Chinese Service): |

| (86) 139 0527 0123 |

| (86-514) 8795 9766 |

| TEL(English Service): |

| (86) 139 0527 6765 |

| (86-514) 8582 9916 |

| FAX:86-514)87958766 |

| E-MAIL:ttepc@ttepc.com |

| ADD:13F, Jiuzhou Bldg, No. 143, M Jiangyang

Rd, Yangzhou City, Jiangsu Prov, P.R.China, 225009 |

|

|

|

Flue gas desulphurization system |

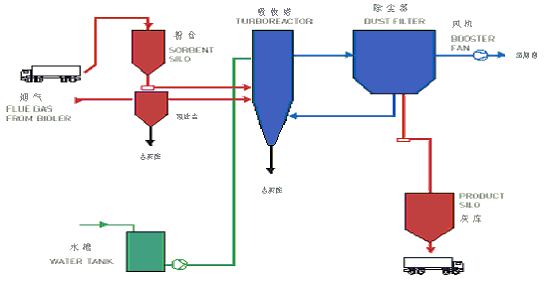

Desulfurization system mainly serves coal-fired power plant, cement factory, firing(pelletizing)factorySemidry method flue gas desulfurization process; circulating fluidized bed (LJS-FGD) desulfurization technology. |

Main Features: |

※The technology is mature and reliable, it has been successfully applied in the fields of power supply, firing, coking, waste and industry kiln stoves;

※One device with 3 functions of desulfurization, dedusting and ash removing, greatly reduces investment and operational cost;

※Energy-efficient, the emission of SO2 below 50mg/Nm3;

※Completely removes SO3、HCl、HF, dispense with anticorrosion;

Exhaust fume requires no heating, free of "white fume" phenomenon;

※Water and energy-saving technology, absorbent and by-products are in dry state, no waste water discharge;

※High degree of automation, simple and convenient start and stop;

※Effectively removes the contaminations of heavy metal, RSP and dioxin in coordinating management.

|

| |

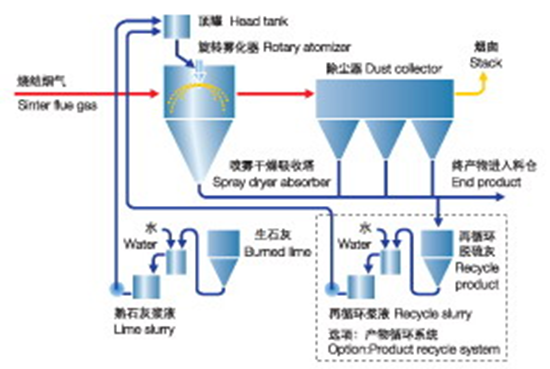

Spray drying absorption techniques(SDA) |

|

| |

SDA Process: |

|

| |

Advantage of SDA process: |

※High reliability, 97%--98% in general. |

※Large operating flexibility, can flexibly adapt smoke load and fume component's large scale fluctuation. |

※High removal rate of SO2, may generally reach more than 90%, maximumly 98%. |

※Completely removes SO3 dispense with anticorrosion and amoke reheating system. |

※Produces no waste water, and may use low quality water, such as river water, sea water and other process waste water. |

※May simply add activated carbon jet bubbler to effectively remove the contaminations of dioxin and heavy metal. |

※May conveniently link up with denitration device. |

| |

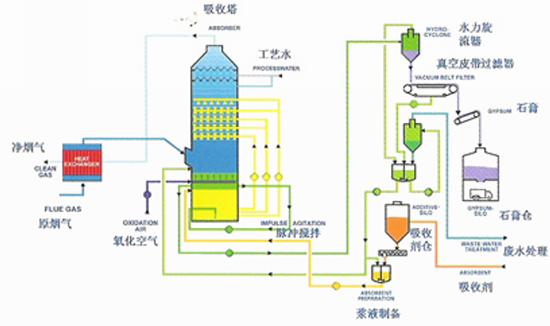

Wet flue gas desulfurization |

| |

Wet flue gas desulfurization is the flue gas desulfurization technology which is most widely used and is the maturest technology in flue gas desulfurization technology.Wet flue gas desulfurization is to wash flue gas with slurry agent at the end of the flue. The desulfurizer and desulfurization products shall be wet. The reaction shall be carried out in solution. The calcium has a high-usage. The desulfurization efficiency can reach to 95% which is the first selected desulfurization process of domestic and overseas large size boilers at present. The main process:limestone, lime-gypsum method has got a further improvement, development and enhancement and it's gradually matured.The feature includes high desulfurization efficiency, high-usage, simple process and low system energy consumption, etc.The wet flue gas desulfurization process mainly includes limestone, lime-gypsum method, simple wet FGD, TFGD, seawater desulfurization technology,magnesia FGD process, wet ammonia flue gas desulfurization(FGD) process,lime-magnesium method and oulopholite method, etc. The adopted desulfatization base includes calcium base, magnesium base, amino base and sodium base desulfurizer, etc.

|

|

| |

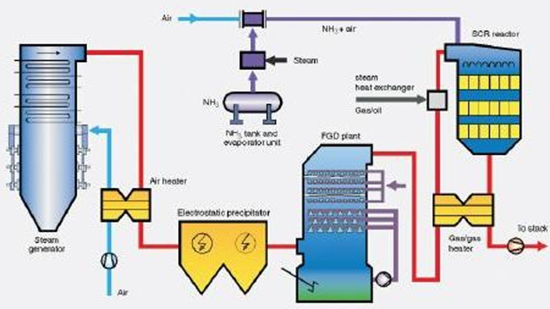

The full spelling of SNCR is "Selective Non-Catalytic Reduction", it is a mature commercialized NOx control treatment technology. SNCR method mainly sprays nitrogenous medicaments into the combustion products containing NO between the temperature range of 870~1,200°C, then reduction reaction happens, NO is removed and generate nitrogen and water. The reduction to NOx by nitrogenous medicaments with oxygen in certain temperature range takes lead in all other chemical reactions and will show selectivity, it is therefore called selective noncatalyzed reduction.

|

SNCR technology is appropriate for various pulverized coal fired boiler, circulating fluidized bed boiler and garbage incinerator, etc. , which enjoys the advantage of extensive adaptation, no matter with the furnace and fuel types.

|

The full spelling of SNCR is "Selective Non-Catalytic Reduction", it is a mature commercialized NOx control treatment technology. SNCR method mainly sprays nitrogenous medicaments into the combustion products containing NO between the temperature range of 870~1,200°C, then reduction reaction happens, NO is removed and generate nitrogen and water. The reduction to NOx by nitrogenous medicaments with oxygen in certain temperature range takes lead in all other chemical reactions and will show selectivity, it is therefore called selective noncatalyzed reduction.

|

SCR technology |

The simple decomposition of NOx under low temperature is feasible in thermodynamics point of view and the reaction can be conducted very slowly, in order to change NOx into N2 , reducing agent such as CH4、H2、CO and NH3 is required to be added during the reaction process. Among them, NH3 is widely adopted in SCR denitration for power plants, currently, nearly all the researches agree that the chemical formula in typical SCR reation condition is: |

4NH3+4NO+O2=4N2+6H2O |

2NH3+NO+NO2=2N2+3H2O |

The above-mentioned reaction may be effectively conducted in the temperature range of 200~450°C by using adequate catalyst. During the reaction, 80% to 9% of denitration rate may be acquired if NOx in exhaust gas and NH3 injected are reacted in the proportion of 1:1 for the amount of substance. NH3 may not be oxidized by O2 , but generates N2 and H2O with NOx selectively during reaction process, the reaction is therefore called "selective". |

|

| |

|

|

|